A concrete joint is a common feature you will meet in most constructions. There can be many reasons to impose a joint in the concrete. Practical limitations, expansion, and shrinkage, separation of structural members are some of them. Various types of concrete joints are available in the field for different requirements. Identifying each of the concrete joints and the purpose is significant to achieve better quality construction.

Different types of concrete joints and the structural purpose

| Type of concrete joint | Purpose |

| Construction joint | Limit the constructional area |

| Contraction joint / control joint | Allow one-way individual movements |

| Expansion joints | Allows thermal expansion movement |

| Isolation joints | Separate the structural members |

| Seismic joints | Allow seismic movements |

Construction joints in concrete

Construction joints are located to facilitate construction operations. In most cases, concrete pour needs to stop due to many reasons. There can be many constraints affecting the size of the pour. Material limitations, the capacity of the machines, the efficiency of the equipment, the pouring area, and the crew’s performance are the key factors among them.

According to the terminology by ACI CT-18, the construction joint is “the surface where two successive placements of the concrete meet, across which it may be desirable to achieve bond and through which reinforcement may be continuous.” This defines two main requirements in a construction joint.

- Two or more, differently aged concrete surfaces should meet in order to have the joint

- Even with reinforcement continuity, the separation between concrete is still valid as a construction joint

Types of construction joints

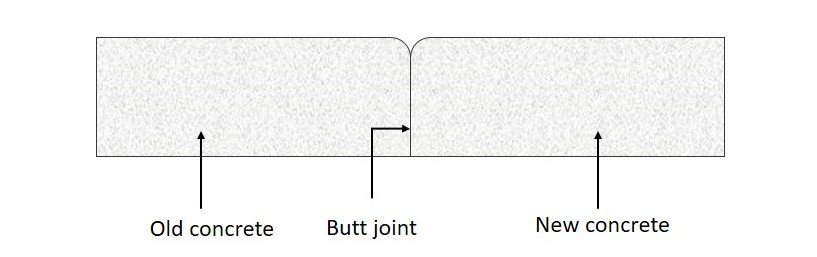

Butt joint

This is the simplest type of construction joint. The joint is in a 2-dimensional plane. Improving the surface texture by chipping will enhance the bonding and shear capacity of the bond. 1/16 inch texture over the surface is considered as roughened. Butt joints are mostly used in pavements and mass concrete in dam constructions

Tie bar joint

Improving the butt joint with flexural continuity is the idea of tie bar joint. The reinforcement bar will transfer the bending and shear to the other concrete. Tie bar joints may be less suitable when exposed to salty water environments because the joint can transmit chemicals to the rebar and cause corrosion.

Tongue & groove joint

This arrangement is mostly using in buildings. The small key & groove arrangement will improve the shear interlocking as well as the water tightness compared to the usual butt joint. A typical section is shown below.

The appropriateness of the construction joint always depending on two main points. First, it is essential to plan the joint location more convenient for the architect, engineer, and contractor. These three parties have different points of view when selecting the location. Architectures always need the joints to be consistent with the design. On the other hand, the engineer wants it to be at least a critical place. However, the contractor every time look for easy implementation.

The common use of a construction joint is framing or defining the construction area. This will allow you to separate each concrete pour from the other and still cast a continuous structure. Introducing a construction joint will reduce the complexness of the pour and mitigate random cracking due to shrinkage and thermal effect. However, placing joints at critical locations can be dangerous. See the following most desired locations to impose construction joints in structural members.

Desired locations for construction joints in concrete

Slabs

Generally, slabs are less in shear forces. It’s good to place the construction joint on a low bending moment location. The contra-flexure point at 1/3rd of the span is the ideal location for the construction joint. Always try to arrange it along a short span direction. This will results you a shorter construction joint and low impact on the bending.

Beams

A similar arrangement of slab construction joint is suitable for the beams too. The middle 1/3rd of the span between two contra-flexure points is the most suitable section for a construction joint in a continuous beam with a uniformly distributed load. Always avoid point loads because of high shear at the area near to them.

Columns

The construction joint in columns is placed at the underside of the beam or slab. Tongue and groove type construction joints are the most suitable ones for columns.

Foundations

Foundations like pad footings are normally cast in one go without any construction joint. You can use the tongue and groove method to connect the column. However, large foundations like rafts may need construction joints to control the heat of hydration. In this kind of situation, proper structural analysis is a must to select the construction joint location.

Additionally, use a binding agents or water-stops to treat the water seepage in fully or partially submerged foundations.

Pavements

Pavements are generally open to harsh environmental conditions and extreme loads. Shrinkage and thermal movements are significant in pavements. In most cases with concrete pavements, tie bar construction joint modified as a movement joint is used. Locating the joint at the highest place will lower the risk of water seeping through the joint.

Dams, tunnels, and canals

When the structure is too long, you have to built it portion by portion using construction joints. In dams and tunnels, these construction joints can lead to leakages. For that reason, copper water stops and rubber water stops are commonly used in these setups to cut the water leaks.

After selecting the construction joint location, perfect execution is mandatory for a quality construction joint. Straight construction joints are always easy and looks good.

A well-executed construction joint can transfer the bending but reduce the shear capacity by at least 40%. On top of that, there can be a risk of corrosion and water leakages reducing the durability of the structure.

How to install a construction joint

- Always plan the location beforehand. Thumb rule is to maintain a distance of 30 times the slab thickness between two construction joints.

- Prepare the sideboards according to the length and the thickness

- Then, install dowel bars if required

- Vibrate adequately near the joint

- Never let the cement grout to leak out. This will create honeycombs along the joint

- Let the concrete to fully dry out before you remove the forms.

- Chip the surface and clean the dowel bars

- Apply bonding agents according to the manufactures recommendations. Normally its immediately before the 2nd concrete

- Finally, pour the next concrete and vibrate adequately

Contraction joint / control joint

Contraction joints commonly used in pavements. Typical thin & long geometry of pavement slabs subjected to shrinking with hardening of the cement. Shrinkage is a common behavior for any structural member. However, this shrink is considerable for lengthy members with no continuing reinforcements.

According to the ACI terminology, the definition is, “formed, sawed, or tooled groove in a concrete structure to create a weakened plane to regulate the location of cracking resulting from the dimensional change of different parts of the structure.” As mentioned, the contraction joint or control joint allows the hydration contraction in the concrete and control random shrinkage cracks by guiding them along the joint.

Select the suitable method for contraction joint

The most common way of creating a contraction joint is weakening the section and allowing the crack to propagate naturally. Installing a 25% weaker plane will ensure the cracking. Therefore for a pavement slab of 4-inch thickness, a 1-inch grove along the planned control joint is acceptable. Sawing and grooving are usual methods for control joints. See the summary of different ways in placing control joints

| Sawing | Tooling | Pre-molded joint | |

| Time | 6 – 18 hours after placing concrete and never delayed more than a day | After finishing the surface but before onset bleeding | Pouring time |

| Machineries / tools | Concrete saw | V grooved trowel | |

| Advantages | Ideal for industrial floors High-quality finish Easy to maintain the depth of the grove | Easy to place | Can overlap with construction joint No need of extra time for the placement The method has no impact on the concrete |

| Disadvantages | Take extra time Can loosen up some of the aggregates If delayed, cracking potential increases | Need to finish the surface again after tooling Hard to cover a large area | Limits the length of a single pour More use of forms and labor |

Best spacing between joints

One of the popular queries with contraction joints is the spacing. It is needed to place contraction joints within desirable spacing to reduce shrinkage cracks. Too much spacing between joints can induce random shrinkage cracks. In addition, it can upset the aesthetic appearance and decrease abrasion resistance as well. According to ACI of contraction, joint depends on the size of minimum and maximum aggregates and also the slab thickness. Below gives the spacing of control of the contraction joint giving to ACI.

| Slab thickness | Max aggregate size less than 19 mm | Max aggregate size is more than 19 mm |

| t | 24 × t | 30 × t |

Expansion joints in concrete

Expansion joints are designed to allow small movement as in control joints. The purpose of the expansion joint is for the thermal expansion movement of the concrete.

Buildings longer than 50 m, bridges, and pavements are the common structures with expansion joints. There are different methods to establish expansion joints. Bridges are commonly used steel grove type expansion joints. While in buildings, a smoother platform joint is mandatory for the users to walk on comfortably. Floor expansion joints, compression seals, and form seals are better for these kinds of structures.

Isolation joint

Even without any requirement for expansion, you may need a joint for the separation of the members. Floor slab on the ground is one of the commonplace to have isolation joints. Furthermore it is essential to separate the foundation pads and columns from the ground slab to allow individual settlements.

Isolation joints typically install as a vertical joint. However, the movement can be in all 3 directions. In many constructions, isolation joints are similarly established as construction joints without continuing reinforcements. It is essential to discontinue the bonding between 2 concrete members in isolation joints.

Seismic joint

Seismic joints are the separation between buildings to accommodate seismic oscillations. When the buildings are too close to each other, providing seismic space is covered by these joints. Seismic joints are different from expansion joints in their performance. As we know, expansion joints typically cover the movement of shrinkage, creep, and thermal expansion of the concrete. In contrast, the seismic joint doesn’t depend on the material properties that much. Most affecting parameters for seismic joint designing is the seismic severity of the building location, its height, and overall stiffness.

Seismic joints are one of the costlier joints you may meet in the construction. Typical width can be calculated using the thumb rule as 2 inches for one story. Just imagine how much of width should be there for high-rise buildings without any damping.