Green cutting is a popular method of roughening the concrete surface using a high-velocity water jet. It is possible to remove the top layer of cement paste using pressurized water when the concrete is still young.

Surface roughening using green cut method is not a complex thing. All you will need is a reliable compressor capable of pressurizing 500 bars, few meters of high-pressure hoses, and a nozzle. The best time to perform green cutting is between the initial setting and the final setting of cement. A laboratory test, according to ASTM C403 is the acceptance test for setting time calculation. Your concrete supplier should aware of these times, ask them, and plan the process.

Green cutting is commonly used in mass concrete constructions like dams, bridges, large foundations, and retaining walls. Compared to the traditional chiseling method, green cutting has many advantages.

Advantages of green cutting

- Speed: With proper equipment & skilled operators, green cutting can cover 5 to 10 times more area than chiseling. It’s all about the right pressure and time. If the concrete is too hard, this method is not practical. Therefore green cutting at the right time is essential for the progress.

- Less human resources: Requirement of the workforce for a green cut is minimum compared to the chiseling method. You only need a nozzle-man and a helper for the work.

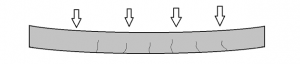

- Better quality surface: Concrete green cutting is more of washing the top cement paste layer. Top few millimeters of the concrete usually contain cement paste because of aggregate settling during the time. If you use traditional chiseling to roughen the surface, the following problems can arise.

- Occurs hairline cracks in aggregate as well as cement paste, causing permeable surface.

- Chiseling can loosen up the aggregate. It will reduce the shear capacity of the surface.

- Improve working environment: Green cutting won’t bring up any dust like in chiseling. It’s easier for the laborers. Also, it is easier to chip and clean the areas close to reinforcement using the water jet.

- Uniform surface quality: With chiseling, the surface roughness can vary over the area. Different workers will chip the surface differently. But with concrete green cut, you can achieve more uniform surface quality regardless of the uneven concrete surface.

Disadvantages

- Suitable time to green cut the concrete is limited. You cannot green cut the concrete at any time you want.

- Specific machinery requirement: Common disadvantage with this method is, it requires power and machinery.

- Handling the water and chipping materials: This method uses high-pressure water. Handling this water on the surface is additional work. Also, the chipping material can clog in drainage making the job hard.

- Increase drying time: Green cutting will improve moisture content in the concrete. It will increase the drying time of the concrete.

The concrete green cutting process

- The concrete green cut process involves air compressor, high-pressure pipes, and nozzle gun. The pressure can vary between 200 bar to 1200 bars depending on the strength of the concrete

- It is best to green cut the surface after initial setting time but before the final setting time. It is essential to check the concrete at the site before starting the work. Sometimes these setting times can vary according to environmental conditions

- Check the surface using a piece of rebar (reinforcement bar). Try to penetrate the rebar to the concrete. If it is easily penetrating the top cement paste layer but not the aggregate below it, you are good to go!

- Properly connect all the pipes and make sure you can cover all the area with the setup

- Green cut from one corner and collect the chipping material to the side

- A fine green cut surface should expose all the top aggregate on the surface.

Summery

Surface preparation using green cut method has better advantages over the traditional chiseling method. Green cut concrete surface shows good bonding as well as minimum permeability characteristics.

Green cutting at the right time and using the right pressures is vital for the quality of the work.

You can use this technique to make an exposed aggregate finish to the concrete surface.