The heat of hydration is one of the main components in concrete hardening. Cement hydration starts immediately after mixing with water. To understand the heat of hydration in concrete, let’s go back to cement production.

Cement comes from processing pozzolana in high temperatures. During the process, Clinker is heated up to 1200 °K temperatures to form Portland cement. Piling up a good amount of energy during the process makes cement unstable. After mixing with water, cement starts its chemical hydration and dissipate energy to become a more stable crystal called concrete.

Of course, concrete is a combination of many materials. But, cement hydration is the key factor that turns the mix of water, cement, and aggregate into the concrete.

Definition of the heat of hydration

According to the ACI terminology, the heat of hydration in cement is the heat that emits by the exothermic chemical reaction between water and cement. Creating new bonds, will emit this heat and turning into more stable cement hydrates. As a result, the temperature of the concrete will increase during hardening.

Hydration heat is common to any type of cement. According to the size of the pour and the material you are using, this heat of generation can be crucial for the concrete. Raft foundations, thick retaining walls, transfer plates in high-rise buildings, concrete dams are some places where the heat of hydration in cement plays a major role.

Factors affecting the heat of hydration

The total amount of heat and the rate can be depending on the chemical and physical properties of cement as well as the size of the pour. Some of the crucial factors affecting the heat of hydration in concrete are,

Chemical composition of cement

Major components of the cement such as C3S, C3A, and C2S contribute clearly to the heat of hydration. C3A and C2A hydrate at a high rate and increase temperature instantly in the mix. However, due to the small amount of those compounds, that high temperature doesn’t last long. C2S on the other hand hydrates at a little low rate and continues to keep increasing the temperature. This makes the hydration last long few days keeping the internal heat at the peak for some time. The behavior of the hydration temperature clearly shows the effect of chemical compounds on the hydration heat of cement.

In addition to the chemical compounds, some additives also create an impact on the heat of hydration in cement. Pozzolanic Portland cement (CEM type IP) is one such cement having an average of 30% fly ash blended to the cement in the manufacturing process. Fly ash is an effective and economical additive for cement. It reduces cement consumption of concrete of hardening of the concrete, allowing more time to dissipate the heat to the environment.

Fineness of cement

The rate of cement hydration increases with fineness. Smaller particles have more surface area than coarse cement particles. That makes more water to contact the fine cement particles at mixing and quick hydration.

Placing temperature

Fresh concrete temperature is one of the key factors that decide the hydration temperature. Basically, if you start at a high temperature you will end up high hydration temperature too. High hydration temperature can result in thermal cracks in concrete.

Placing temperature solely depends on the initial temperatures of mixing materials. So, keeping them at a low level makes the fresh concrete cooler. Usually, it’s easy to control the fresh concrete temperature by the following methods.

- Use of ice and chill water for concrete mixing

- Aggregate cooling

- Do mixing at night times

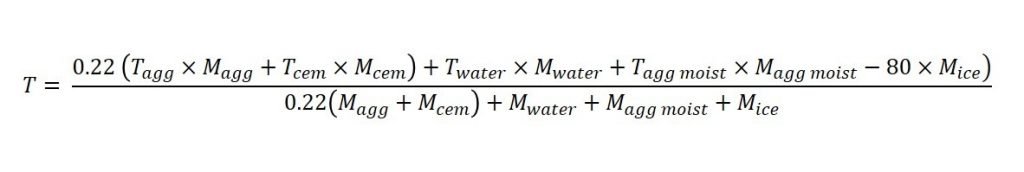

You can calculate the fresh concrete temperature if you know the mix proportions as well as their temperatures. Use the following equation to calculate the fresh concrete temperature.

Environmental temperature

Environmental temperature can vary the setting rate and peak temperature. Hot weather conditions increase the hydration reaction causing a fast setting. This will increase the peak hydration temperature compared to cold weather concreting.

The effect of the environmental condition on concrete hydration temperature can be modeled using computer software. Concreteworks is such simple software that you can incorporate most of the environmental data on predicting the peak hydration temperature of concrete.

Amount of cement & slump

Cement is the main ingredient responsible for hydration heat in concrete. Cement rich mixes produce high heat during hydration. Standard Practice for Selecting Proportions for Normal, Heavyweight, and Mass Concrete, ACI 211.1, roughly estimates the temperature rise in concrete by 50 kg of cement per 1m3 will be about 5°C to 7°C in 18 to 72 hours.

Several factors are deciding the cement content in the mix. There can be various reasons you have high cement content. Maintaining slump while keeping the W/C is one of the reasons to use high cement content.

Another reason is the maximum aggregate size. When aggregates are small the surface area increases. You will need more cement to coat them.

Size of the pour

Concrete pours with a minimum dimension is more than 1m requires special attention on managing the heat of hydration. In large foundations and concrete dams, you encounter 20 m ~ 30 m size concrete pours. In these cases, you need to stick to smaller lift heights or another method like post cooling.

I have my own experience on 25 m × 25 m × 1.5 m concrete pour which subjected to thermal cracking largely. For that much volume, multiple remedial measures should adopt to control the heat of hydration.

Admixtures using

Some admixtures like accelerators can boost up the hydration and provide an instant set. These are common for shotcreting works. However, accelerating admixtures will results in the concrete to hydrates quickly and generate high heat.

When using fly ash in the concrete, it slows down the hydration rate allowing more time to dissipate heat to the environment. Adding fly ash is helpful to reduce the heat of hydration in concrete.

See how fly ash can use to maintain the heat of hydration while achieving the desired strength.

Pros & Cons of the heat of hydration

Among many disadvantages, one of the positive impacts of the heat of hydration will be the heat contribution during cold weather conditions. It really helps to maintain the optimum temperature for concrete to hydrates. However, too much heat energy will cause thermal cracks in the concrete. Large mass concrete pours always need much attention in this regard.

How to control the temperature rise in concrete

Tune the mix design

Before getting into any on-site measures, you can try adjusting the mix design and reduce the cement content. High workability demand can consume more cement in the mix design. Try to add some admixtures to hold up the workability without affecting W/C.

Chute and belt conveyor methods need less workability compared to concrete pumping. If the structure permits, adopting those methods, or reducing the length of the pump line will work on that.

Minimize the voids in the concrete mix by optimizing the mix. That way you need less cement to fill the voids. Add more fine particles to fill out the voids. However, you need to carefully inspect the variation of workability when adding fines.

Add some fly ash to the mix. It will reduce the hydration rate so that heat dissipation is easy. It is proven that adding fly ash will reduce the peak hydration temperature in concrete.

Do some simple modeling work to predict the peak hydration temperature in concrete. I use “ConcreteWorks” program for this. It incorporates all the important parameters to predict the peak hydration temperature of common mass and reinforced concrete elements.

Using low heat or pozzolanic Portland cement is effective to reduce the heat of hydration in concrete. Low heat cement is a bit costly than the PPC, but it is more efficient.

Chill water and ice

The use of chill water and ice is the most common and easiest way of adjusting the fresh concrete temperature. When the placing temperature is low, the peak value will reduce according to that. Try different combinations of ice and chill water to reduce fresh concrete temperature to the desired level.

Aggregate cooling

Aggregate cooling is another method to reduce the fresh concrete temperature. Although the cooling setup is expensive and needs separate supervision this method can reduce the fresh concrete temperature further.

Post cooling

Circulating cold water through a pipe network embedded in the concrete is one of the oldest methods continuing to reduce the peak hydration temperature. Temperature and required flow rate will depend on the total heat generated in the concrete. We use 1m × 1m × 1m spacing between the pipes and 15°C to 20°C water temperature for concrete with fresh temperature below than 28°C.

Nighttime concreting

Arranging the concrete pour at night time can adjust the peak temperature by 2°C to 4°C according to the environmental conditions.

Steel forms

Steel forms perform better compared to wooden forms in dissipating heat. Easy heat dissipation will allow the concrete to cool down fast and peak temperature will reduce.